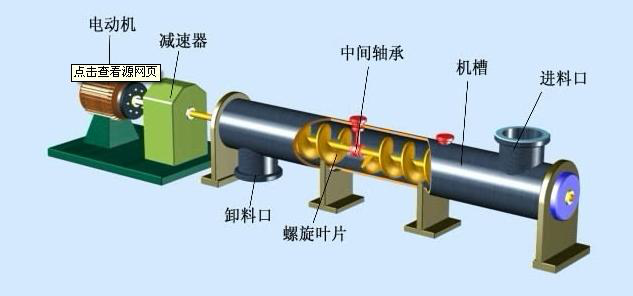

Grain machinery and equipment Screw conveyor installation and operation guide

The installation of grain machinery and equipment is relatively not particularly strict, because in itself the relative requirements are relatively low. Provide a conveying equipment installation operation guide for your viewing pleasure. If there is wrong place you more tolerance.

1.Installation

(1) Before installation, the conveyor should be checked whether it is in good condition, whether the parts are defective or not, and whether it is deformed by bumping during transportation.

2) Measure the size of the hole reserved at the installation place, whether it matches with the size of the mounting hole of the support plate of the conveyor, and fix it firmly with bolts or expansion screws in accordance with the size of the hole.

The size of ground bolts is as follows:

3 ) When connecting the machine troughs, first put the bolts of each section through, straighten them with a line, and connect them according to the line to ensure that a line is formed after connection.

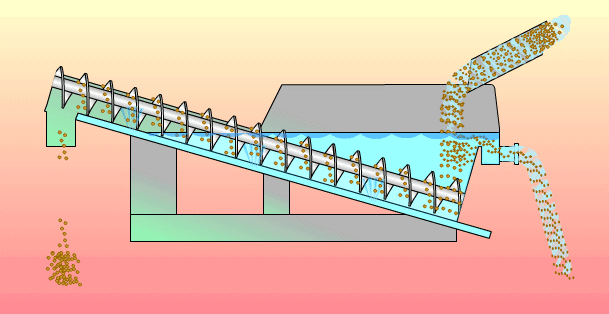

4 ) Conveyor inlet and outlet can be set flexibly according to the needs of the site, can be set up a, can also be set up more than one (round, square), in and out of the inlet and outlet broken welding sealant.

5) The center height of the motor and the center height of the conveyor should be the same, and the two couplings should be tightened side by side and fixed with fastening screws.

2. Inspection and commissioning

1 ) The centerline of the machine trough and the shaft of the stringer should maintain a good coaxiality, can be adjusted up and down by the boom.

2 ) The machine trough should be tight at the joints of each section, there can be no misalignment, there are gaps in the sealant, the machine trough and the cover with a sealing strip between the dust.

3) The inner wall of the machine trough and the gap around the winch shaft should be consistent.

(4) The length of the machine groove and the length of the stringer shaft can be adjusted through the middle of the connecting shaft of the small slide.

(5) After installation, connect the power, test run, see the operation of the conveyor.

This belongs to the selection of materials

3 Operation

Before starting the conveyor should be a comprehensive inspection, the appearance of cleanliness check, check all parts of the oil dirt; machine intact state check, check the body of the body with or without bumping deformation, site installation of the screw shaft coaxiality; check the connecting parts, found to be connected loose, to exclude; check the flexibility of operation, to see whether the screw shaft is running flexibly, with or without stagnation phenomenon, abnormalities found in a timely manner to exclude the squeaky noise parking, and then tighten the bolts. Open the middle small cover plate, loosen the boom bolt, start the machine to let the spiral shaft rotate, automatically find the balance, and then tighten the bolt. Check the bearing temperature, found that the temperature rise over 70 °, should be shut down to find out the cause, to exclude; check the shaft end seal, found that there is leakage, find out the cause to exclude.

4. Common faults and troubleshooting:

Screw conveyor due to conveying materials in a small space, very sensitive to the material; screw shaft rotation is prone to material entanglement; hanging in the middle of the easy to block the material, so the clogging is a common failure of the screw conveyor, the occurrence of clogging will affect the output of the lighter, increase power consumption, the severity of the motor will be burned, twisted off the screw shaft, affecting the normal course of production. There are many reasons for clogging, and the following measures can be taken to prevent clogging:

(1) Reasonable selection of various specifications of the screw conveyor.

(2) strict implementation of the operating procedures to achieve no-load starting, no-load starting, to ensure that the feed continuous and uniform.

(3) to enter the conveyor material for the necessary cleaning, to prevent large or fibrous impurities into the machine caused by clogging.

(4) Increase or lengthen the discharge port if the discharge is not smooth.

(5) Install bin leveler and blockage sensor to realize automatic control and alarm.

(6) Open anti-blocking movable door on the cover plate of the tail end, when blocking occurs, the material will open the anti-blocking door to unload the material.

This description is prepared according to the national standards and the actual production and use experience of the product.