The jacking transfer machine is generally used to change the conveying direction of the articles, feeding or moving the articles from the forkway into or out of the main conveying line. It is characterized by large load bearing, simple structure, stability and reliability. In roller conveyor, chain conveyor, for sorting speed less than 30 pieces / minute, but the weight of a single item is more than 2000kg, it is recommended to choose the top lift shifter.

Contact Now

Product description:Reciprocating vertical elevator, also called elevator, escalator, is just a lift equipment in the up and down reciprocating conveyor.Features of reciprocating elevator:Reciprocating elevator is driven by the chain, through the frequency conversion speed control motor, the lift car up and down reciprocating movement. The elevating car is equipped with a transmission mechanism, so that the conveyed objects automatically enter the elevator car on the elevator.

Contact Now

Inclined Guide Wheel Sorting System: When the rotating inclined leader wheel, floating up and down in the gap of the main narrow belt arranged in parallel, to achieve the purpose of sorting goods.Inclined guide wheel sorter is a kind of automatic sorting system widely used in the logistics centers in the United States and Japan after World War II, and the system has now become an indispensable part of large and medium-sized logistics centers in developed countries.

Contact Now

Product Description:Continuous Vertical Elevator is a new type of vertical vibration conveying equipment, which is mainly applied to the lifting and conveying of box-type components, and is divided into two kinds of Z-type vertical elevator and C-type vertical elevator according to the direction of the inlet and outlet ports. For all granular, lumpy, powdery solid materials (viscosity is not big) can be conveyed. Vertical conveyor can complete the drying and cooling of materials while lifting materials upward.

Contact Now

Spiral vertical elevator, is a large mechanical equipment for transportation by changing potential energy, such as mine elevator, over dam hoist, etc. Broadly speaking, elevators, overhead cranes, winches, stable cars, cranes, starters, etc. can be called hoist. Elevator generally refers to the larger power, lifting capacity of large mechanical equipment.Spiral elevator, is a large mechanical equipment for transportation by changing potential energy. Such as mine hoist, over the dam hoist. Broadly speaking, elevators, overhead cranes, winches, stable cars, cranes, starters, etc.

Contact Now

Rotary table elevator is a large mechanical equipment for transportation by changing potential energy, such as mine elevator, over dam hoist, etc.. Broadly speaking, elevators, overhead cranes, winches, stable cars, cranes, starters, etc. can be called hoist. Elevator generally refers to the larger power, lifting capacity of large mechanical equipment.It is used to vertically lift limestone, coal, gypsum, clinker, dry clay and other lumpy materials through the crusher, as well as raw materials, cement, coal dust and other powdered materials.

Contact Now

Chain Conveyor/Mesh Chain Conveyor/Chain Conveyor Line/Chain Assembly Line is widely suitable for automatic conveying, distributing, and in-line conveying of back-channel packaging for food, canned food, pharmaceuticals, beverages, cosmetics and detergents, paper products, condiments, dairy and tobacco.Chain conveyor can meet the requirement of single column conveying of beverage labeling, filling and cleaning equipment, and meet the requirement of large quantity feeding of sterilizing machine, bottle storage table and cold bottle machine, and the head and tail of two chain conveyors can be ma

Contact Now

Manipulator carton palletizer is to palletize the already loaded products on the pallet according to a certain arrangement for automatic stacking, which can be stacked in multiple layers, and then push out for forklift transportation to the warehouse for storage. Realize intelligent operation and management, simple and easy to grasp.

Contact Now

The birth of electronic weighing, so that the electronic scale products have been generally improved, especially microcontroller technology and electronic strain principle of the load cell in the weighing category, so that the electronic balance is more stable, intuitive and fast, and broke the traditional scale single weighing concept, to develop into a dynamic weighing, process weighing, data storage/output, and greatly improved work efficiency. Into the new century, the rapid development of electronic technology, electronic scales and electronic balances price significantly lower.

Contact Now

Palletizer is to code the cartons which have been loaded into containers on pallets, trestle boards (wood, plastic) according to a certain arrangement for automatic stacking, which can be stacked in multiple layers, and then rolled out for forklift trucks to transport to the warehouse for storage. This equipment adopts PLC+touch screen control to realize intelligent operation and management, which is simple and easy to grasp. It can greatly reduce labor force and lower labor intensity.

Contact Now

A robotic arm is an automatic operating device that imitates some of the movement functions of the human hand and arm, and is used to grasp and carry objects or operate tools according to a fixed program. Characterized by a variety of expected operations can be programmed to complete the construction and performance of both human and robotic arm have their respective advantages.

Contact Now

Automatic carton opener:Automatic carton opening machine is also called carton automatic molding bottom sealing machine, the method is to open the carton board, the bottom of the box folded according to a certain procedure, and sealed with the tape and conveyed to the carton loading machine special equipment.

Contact Now

Roller Conveyor/Power Roller Conveyor/Roller Conveyor/Roller Line (also known as Roller Conveyor) is suitable for all kinds of boxes, bags, pallets and other pieces of goods, can convey a single piece of material with a large weight, or to withstand a large impact load, has a large conveying capacity, fast speed, fast operation, and can be realized for many varieties of common line shunt conveying characteristics.Structure form: according to the driving mode can be divided into power roller conveyor and powerless roller conveyor, according to the arrangement form can be divided into horizontal

Contact Now

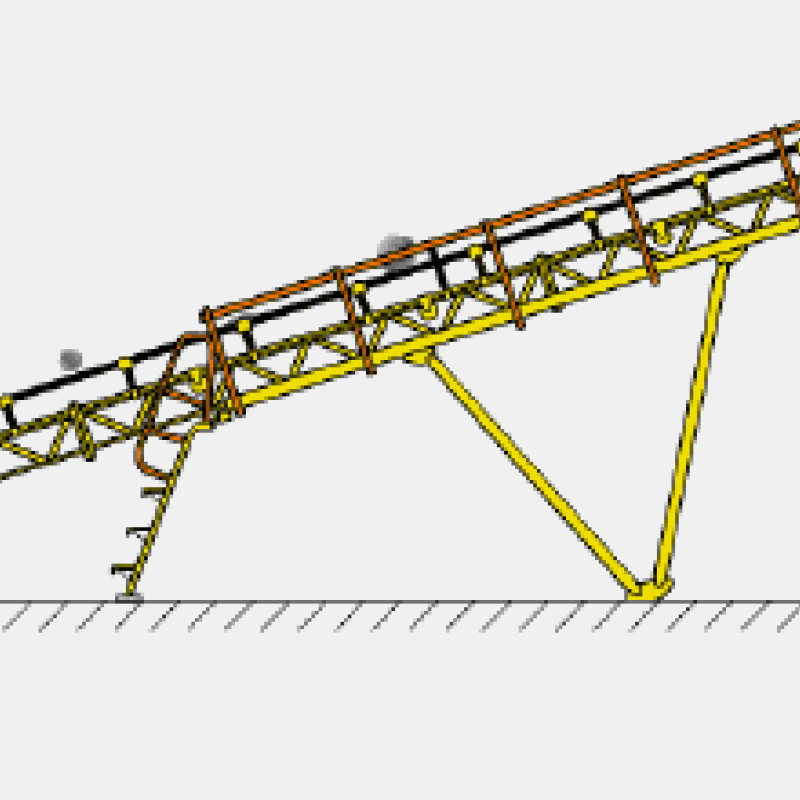

Telescopic conveyor (also known as telescopic loading machine), it can be freely retracted in the length direction, control the length of the conveyor at any time.

Contact Now

Belt conveyor uses the continuous or intermittent movement of the conveyor belt to convey various kinds of light and heavy goods, which can convey various kinds of bulk materials, as well as various kinds of cardboard boxes, bags and other single piece of goods of small weight, with a wide range of uses.The materials of conveyor belts are rubber, rubber-plastic, PVC, PU and so on. In addition to the transportation of common materials, the conveyor belts can also meet the transportation of oil-resistant, corrosion-resistant, anti-static and other materials with special requirements.

Contact Now

Automated Sterilization Conveyor Line is an efficient and intelligent equipment designed to meet the needs of manufacturers for sterilization and conveying in the production process. The product transforms traditional manual operation into mechanical automation, greatly improving production efficiency and product quality.The equipment has an intelligent control system, which can monitor and adjust the working status of the equipment in real time.

Contact Now

Pallet dismantler is used in pallet conveyor system, it is used in combination with various conveyors to collect or distribute empty pallets to the conveyor line.a.

Contact Now

Slider Sorting, which is a special form of slat conveyor. The surface of the conveyor is composed of metal slats or tubes, such as bamboo mats, and on each slat or tube there is a guide slider made of hard material, which can slide along the slats in a transverse direction.

Contact Now

Side automatic baler adopts the structural form of side-mounted movement, which is especially suitable for bundling cartons with dust, liquid and seafood and other packages, without worrying about the abrasion and corrosion of the movement by dust, water droplets and other corrosive liquids.The conveyor is equipped with a ball-type touch switch to facilitate automatic operation.

Contact Now

The jacking transfer sorter is widely used in automatic warehousing and logistics system. The logistics box or packaging box for diversion, merging and so on. Sorting operations are non-South-South operations in physical systems. This equipment can be used in diversion and distribution operations. Diversion refers to the conveyor line along the lane conveying direction into two lines of transportation, generally the goods are divided into major categories of transportation.

Contact Now

Automated Sterilization Conveyor Line is a state-of-the-art equipment that adopts advanced automation technology, which is capable of realizing efficient, fast and safe sterilization treatment and conveying of items. This equipment is widely used in pharmaceutical, food, chemical and other industries, especially suitable for the scenario of sterilizing microorganisms, viruses and bacteria.This automatic sterilization conveying line is mainly composed of transmission system, sterilization system, control system and safety protection system.

Contact Now

Product description:Case sealing machine (Case sealer machine) is mainly used for carton sealing packaging, both stand-alone operation, but also with the assembly line supporting the use of it can be a single box operation, but also with the carton molding machine, carton loading machine, labeling machine, strapping machine, pallet stacker, conveyor and other equipment supporting the use of packaging lines, packaging assembly line operations must be equipment.

Contact Now

Medical material palletizing and packaging line is a kind of equipment specially used for material packaging in medical industry.

Contact Now

The main components of the packaging line of automatic barrel coding machine include conveying system, metering system, sealing system and palletizing system. The conveying system can stably and quickly convey the products to the designated area to ensure the smoothness of the subsequent operation. The metering system is equipped with high-precision weighing function, which can automatically distribute the products according to their weights and ensure the accuracy of the products in each packaging drum.

Contact Now